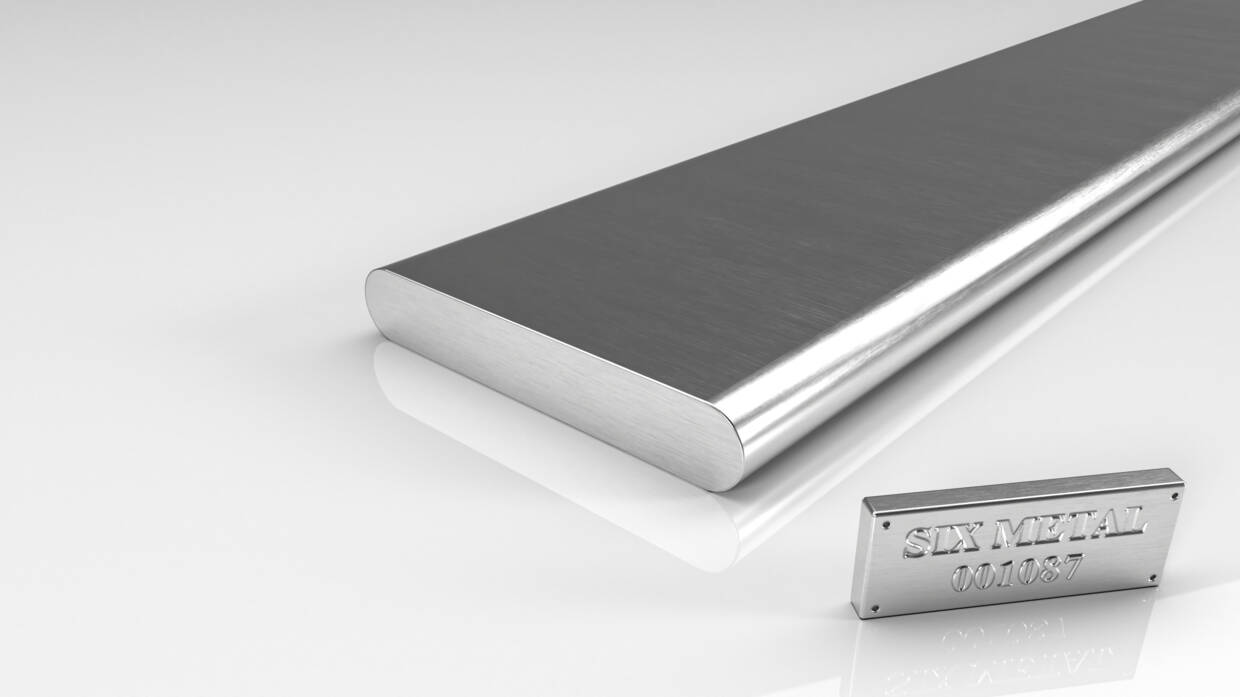

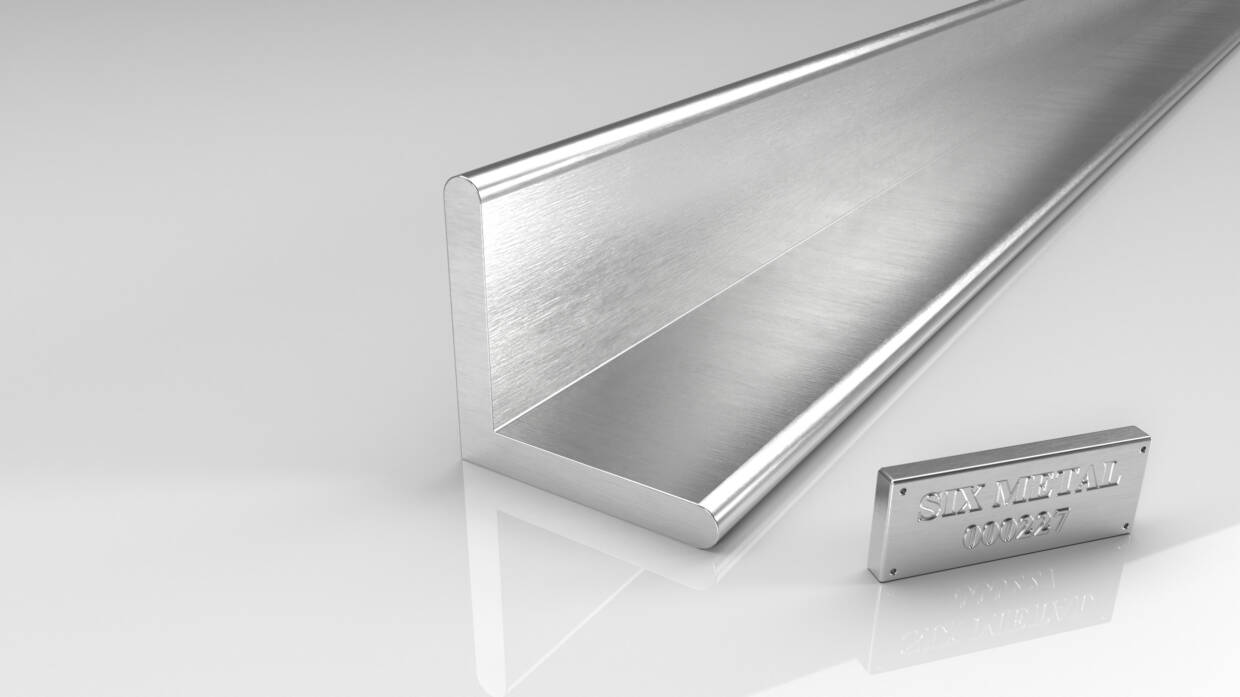

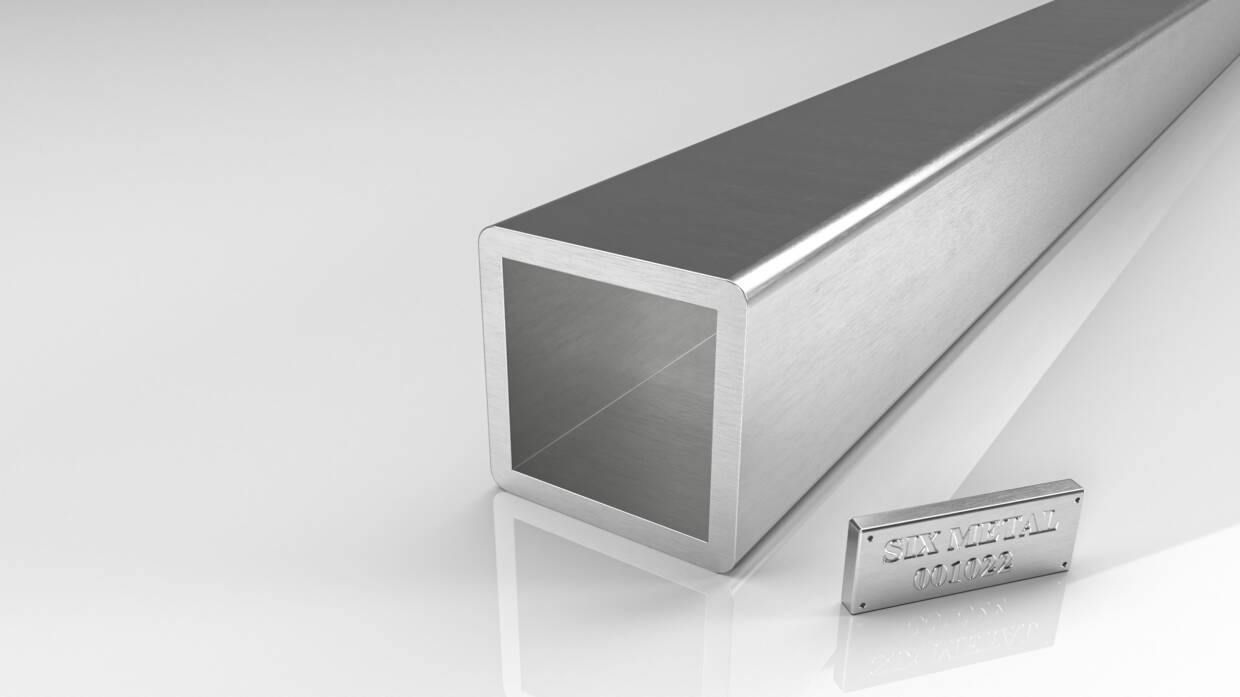

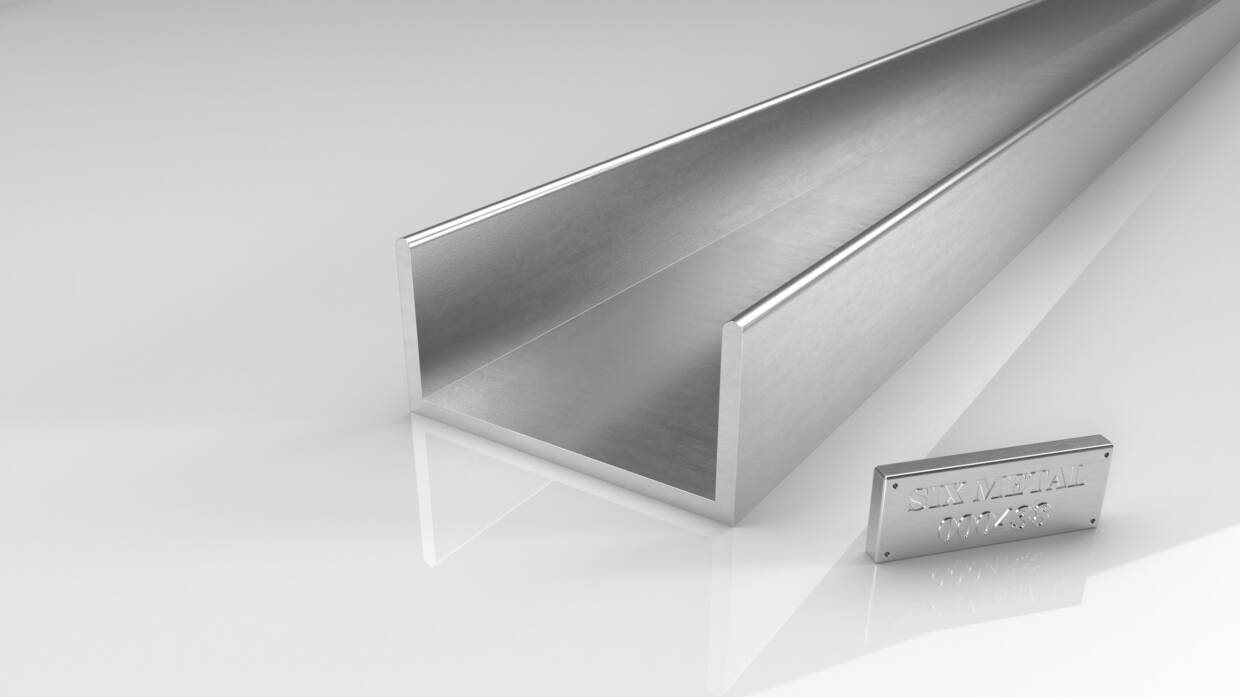

Anodizing is one of the practices that add value and additional benefits to aluminum profiles. Six Metal and his solution partners improves the quality of their process by anodizing to increase the corrosion and heat resistance of its aluminum profiles.

Thanks to this practice, our clients can enjoy their aluminum profiles for a lifetime and produce better quality products. In the simplest term, anodizing is the process that offers a special coating on aluminum. It is also known as the electrolysis process.

We offer aluminum profiles with an oxide layer with the help of an electric current. Later on, these profiles are painted to eliminate the porous structure that occurs due to the electric current. This process also provides additional durability and strength to the aluminum.

With anodizing department, we offer custom solutions according to the demands and expectations of our customers. This means that we can offer varying coating thicknesses depending on the usage purposes of our aluminum profiles. In addition to this, we can offer colored profiles depending on your requests.

If you would like to benefit from aluminum profiles that are coated with the most advanced anodizing methods, we are waiting for your call. You can always contact our expert team to learn more about customizations or request a free quote.