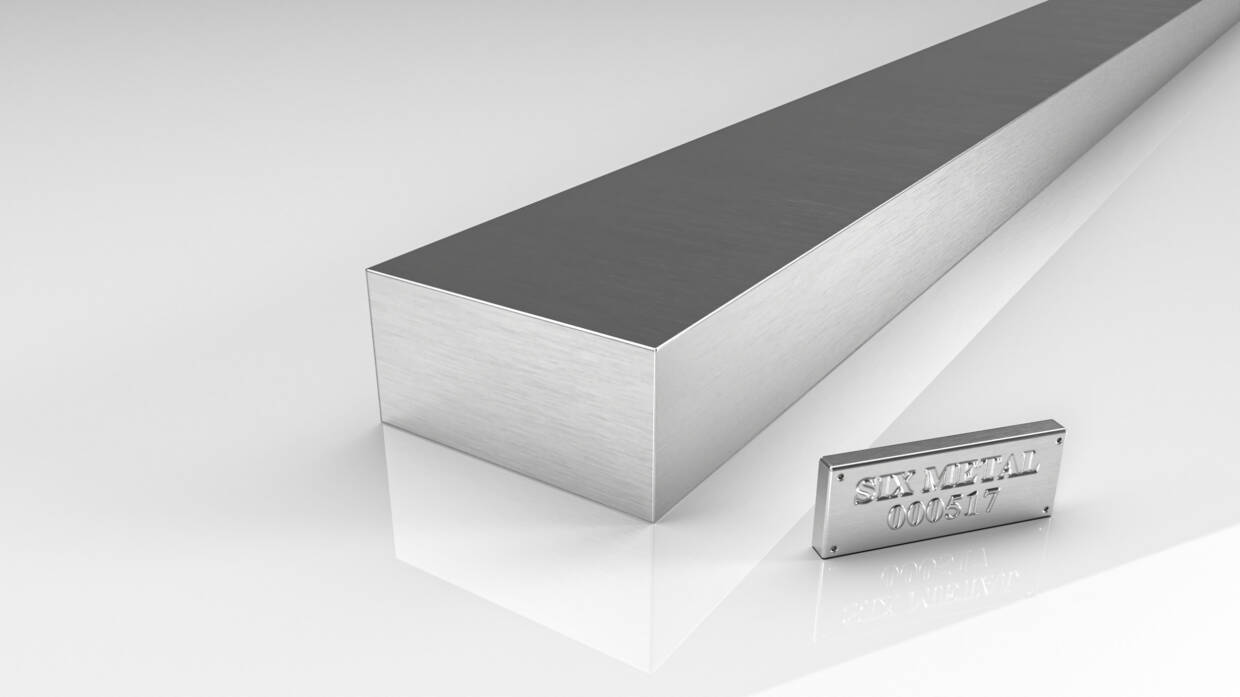

Customization is one of the important factors that determine the success of businesses. Today, most consumers are looking for extraordinary designs with unique colors. Thus, as Six Metal, we and our solution partners provide solutions to our clients by dyeing our aluminum profiles with various colors.

Besides offering a wide range of color options, we also offer different brightness alternatives. Our solution partners benefit from the most recent techniques and equipment to ensure a flawless powder coating process for aluminum profiles.

As Six Metal, we only offer industry standard and top-quality dyes to provide added durability and resistance against corrosion and UV effects. This helps us to offer quality as well as long-lasting aluminum profiles. Our clients can request any color, shade, or brightness for their custom orders.

We and our solution partners also pay attention to our environment and prefer organic solvent-free dyes as surface chemicals. Such dyes do not have any adverse effect on the environment as well as human health. Thus, they can add value to your products and processes.

If you have any questions or concerns about our powder coating processes, please feel free to contact us. Our customer representatives will be happy to serve you and submit a free quote for your orders and requests.