Learn More

Learn More

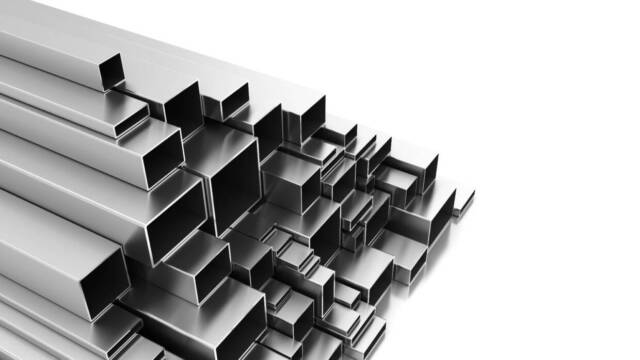

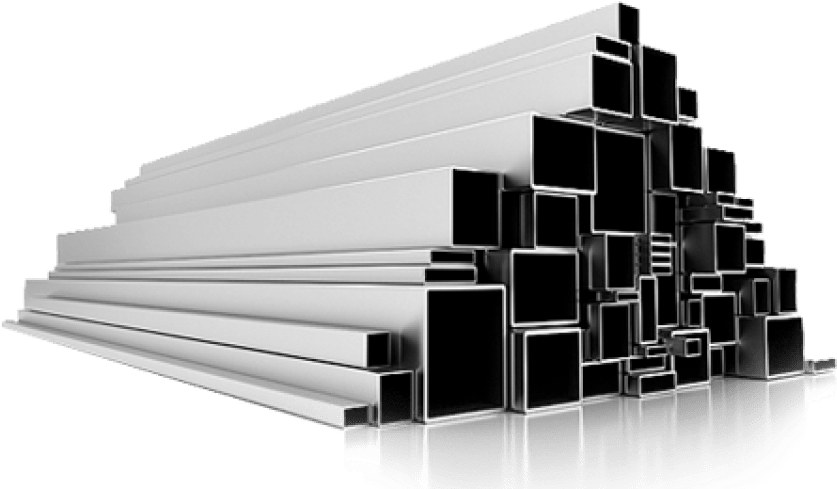

Aluminium Profiles

And More...

Products

Products

Architectural Systems

Best solutions for door&window systems

Products

Products

Solar Profiles

Best solutions for solar systems

Learn More

Learn More

Anodizing

You can find here the Best Anodized profiles

WHY SIX METAL?

Six Aluminium specializes in customized aluminium solutions and values long-term relationships with its customers. Leveraging our expertise in product quality and supply methods, we can cater to your design and development needs.

Our team is dedicated to providing exceptional service and we offer a wide range of products with press lines ranging from 1250 to 5500 tons. We are equipped to meet all your requests, from 0.020 kg/m profiles to 70 kg/m.

Our commitment to quality has helped us build a loyal customer base that recognizes and appreciates our efforts. We take pride in delivering only high-quality products with short and reliable delivery periods.

Considering all these factors, we are confident that Six Metal can be an excellent business partner for you. We look forward to the opportunity to be your next aluminium supplier.

Innovative Solutions

We are an aluminium supplier company that is available to assist you at any time. Our core values are centered on quality, trust, and timely solutions. We are committed to providing you with our best efforts to meet your specific needs. As your solution partner, we strive to be both innovative and reliable, delivering results that you can count on

Advantages of Aluminium

Aluminium is one of the most lightweight metals available today. It offers easy design and shaping capabilities while being extremely durable. The versatility of aluminium allows it to be softened, processed, shaped, extruded, and manufactured into a wide range of products for various applications. Some of the products that incorporate aluminium include cans, kitchen utensils, foils, window frames, constructions, special designs, beer kegs, and airplane parts. With its adaptability and broad range of uses, aluminium has become a popular choice for many industries.

Lightweight

The low thickness and high weight-to-power ratio of aluminium provide numerous benefits for a wide range of industrial applications.

Resistant

Aluminium boasts strong resistance to various weather conditions and is also resistant to corrosion from many acids. Additionally, it has the added benefit of being an effective reflector of both visible light and heat.

Easy To Process

Aluminium is a highly suitable metal for extrusion processes, as its alloys can be processed quickly, resulting in faster production times. Once mold production is completed, the desired alloy can be used directly to begin production.

Easy to Form

The use of cold or hot forming methods, such as rolling, extrusion, and forging, in combination with aluminium alloys, enables the production of a wide range of cross-sections.

Recyclable

Recycling used aluminium parts to produce new materials is a viable option. Moreover, aluminium recycling is an energy-saving process that reduces the amount of energy required in production.

Durable

Through alloying and appropriate heat treatment, aluminium can achieve mechanical properties that are comparable to steel. As a result, it has become an integral component in various industries, including automotive, defense, machinery, aerospace, and many others.

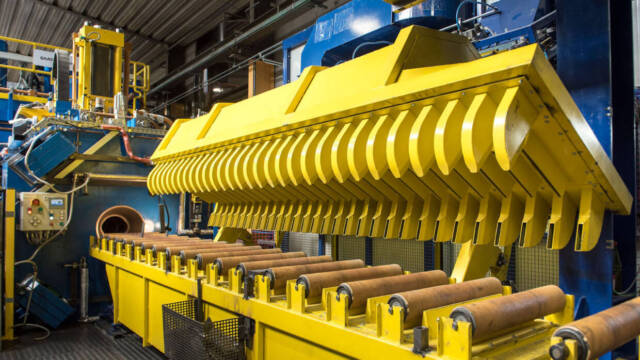

PRODUCTION PROCESS

LEARN MORE ABOUT THE PRODUCTION PHASE

Our clients, who place their trust in our experience and quality standards, can benefit from our die house, extrusion, anodizing, powder coating, mechanical processing, quality control, and packaging services. Six Aluminium provides comprehensive solutions to its customers in various industries.

CONTACT US

LEARN MORE ABOUT US

As Six Aluminium, a reliable supplier of aluminum products, our top priority is to provide our customers with high-quality solutions and services that stand out from those of other suppliers. If you have any inquiries or want to learn more about our products and services, please do not hesitate to contact us. We are always ready to assist you in finding the best solution for your needs.

LEARN MORE ABOUT ALUMINIUM

Modern Aluminium Facade Systems Elevating Spanish Architecture

Sustainable Construction with Customized Aluminium Solutions in Germany

Happy New Year 2024

Shutters: Durability Meets Design

How Aluminum Round Tubes are Made

How to Choose the Right Aluminum Round Tube for Your Project

The Benefits of Aluminum Round Tubes for Industrial Applications

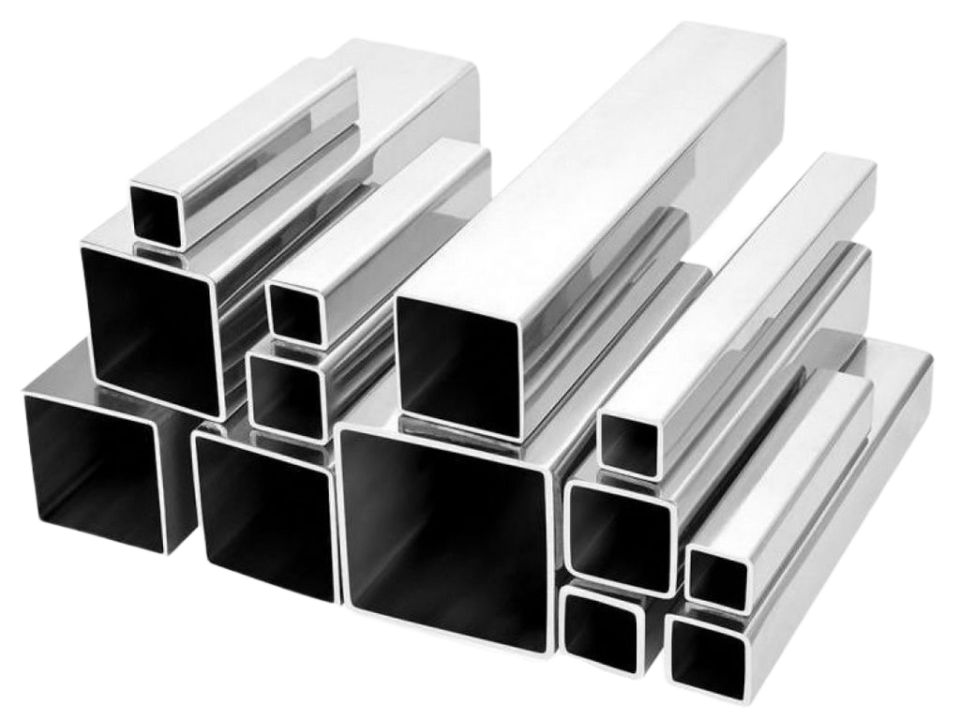

Advancements in Aluminum Rectangular Tube Technology

Fabrication of Aluminum Rectangular Tubes

Introduction to Aluminum Rectangular Tubes

Why Aluminium ?

Aluminum extrusion is a process used to create specific profiles of aluminum in desired lengths. The process is relatively simple; the die remains fixed, and the aluminum billet is pushed through the die using a moving ram.

The extrusion process is used to produce a range of solid rods, bars, and hollow tubes. The die's structure can be altered to manufacture various hollow and solid profiles.

The melting point of aluminum is around 660°C, and extrusion typically occurs with billets heated to temperatures over 375°C, and sometimes as high as 500°C, depending on the alloy.

Aluminum extrusion is commonly used in construction, automotive and aircraft manufacturing, industrial machinery, and consumer goods. Extruded shapes can be divided into three main categories: solid, without any voids or openings; hollow, with one or more voids; and semi-hollow, with a partially enclosed void.

When metals are exposed to specific conditions such as air and humidity, a metal-oxide layer is formed on the exposed surface. This layer is inert, which means it no longer reacts with the conditions in the same way the pure metal does.

Similarly, when aluminum comes into contact with moisture or air, it naturally forms a layer of oxide. This oxide layer is not excessively porous or flaky, and it serves as protection by preventing further oxidation of the aluminum.

Powder coating aluminum extrusions offers a multitude of benefits. Firstly, it provides a wide array of vivid, vibrant color choices. The coating is applied in a thick layer that adheres well to the aluminum, minimizing the risk of flaking or peeling. The finish can last up to 20 years, thanks to its resistance to chemicals, weather, and corrosion.

Powder coating is highly efficient, with minimal waste produced during the application process due to the use of electromagnetic energy. It is also an environmentally friendly option, as it does not contain harmful solvents. Additionally, it is a cost-effective solution that offers durability, high-quality finish, and low maintenance requirements.